Quick start with new floor: decoupled covering for many HP

Raising little dust and showing off the expensive vehicles to their full advantage – this was the requirement for the laying of the new tile covering in the Mercedes car dealership in Luxembourg. Milling off the old epoxy resin coating was out of the question, because sales were to continue with as little interference and dust as possible. The solution: a floating covering support and decoupling system.

An elegant car dealership with many exclusive models and two major challenges: a new, large-format floor covering with large tiles was to be laid on more than 1,600 square meters of exhibition space at the Mercedes dealership in Luxembourg, which would put the vehicles in the right light in future. And without a break, because operations had to continue on a smaller area during the construction phase, during which no dust was allowed on the vehicles. An exciting project for tiling company Fliesen Simmers from Echternach.

Complete decoupling

The existing substrate, a thick layer of epoxy resin coating, turned out to be the next problem, because epoxy resin is not suitable for bonded installation. The surface also had additional separating layers due to the cleaning. But milling would have been extremely difficult and dusty on this large area. It therefore made sense to completely decouple the covering structure.

Reliability by means of floating installation

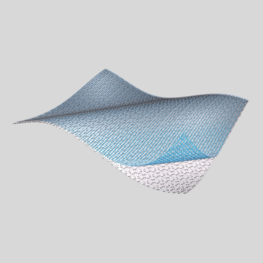

The coverings are permanently protected from damage with a floating decoupling mat.

Covering carrier and decoupling in one

Normally, decoupling systems are glued to the substrate. But due to the anti-adhesion epoxy resin floor, only a floating system could be used. Only one product currently offers these properties: IndorTec 2E from Gutjahr. A highly tear-resistant glass mesh reinforcement is laminated onto the film-like mat. All joints are provided with joint reinforcement. This creates an independent pavement carrier with which a functional pavement structure can be created - without bonding to the substrate. The floating installation completely decouples the covering from the substrate.

Another advantage of this system: the renovation can be carried out particularly quickly. IndorTec 2E can be installed around 50 percent faster than other systems. Because the preparatory work which is otherwise usually required is completely eliminated.

Continuous appearance

In the Mercedes car dealership, large porcelain tiles were embedded in adhesive mortar on the IndorTec 2E decoupling mats. Due to unevenness in the substrate, the layer thickness was between 5 and 10 millimetres. With the large contiguous covering areas it was important for the mortar to set quickly and above all without shrinkage, because this is important for the functionality of the completely decoupled covering structure.

The new type of laying has also been beneficial for the appearance, because the expansion joints in the substrate did not have to be taken over 1: 1. The result was a visually continuous surface made of large tiles which can easily support vehicles weighing up to 2.5 tonnes.

Step by step laying

Thanks to the quick and simple system, laying could take place one step at a time. Areas of the showroom were able to be used without restrictions during the entire period, without dust and without dirt – just like the client wanted.

Products used

Similar project reports

![[TRL] Gutjahr Systemtechnik GmbH - Komplettsysteme für den Außen- und Innenbereich](/build/images/gutjahr-logo.d62773db.svg)