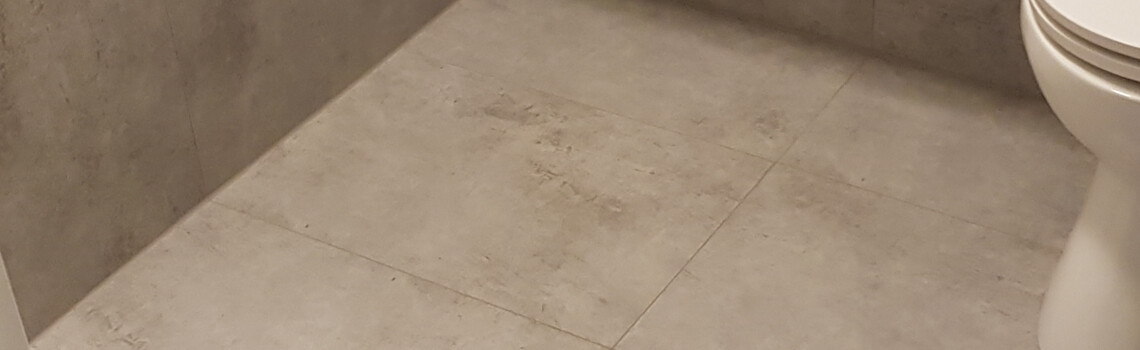

Bathroom renovation with underfloor heating

Refurbishing the small bathroom and installing underfloor heating: this was a major challenge on a construction site in Bensheim in southern Hesse. Because on the one hand the screed was cracked, on the other hand the construction height was low. But the tiler came up with the idea of using special underfloor heating – one that not only heats, but decouples and seals at the same time.

The client and his wife now come to the new bathroom in the mornings and have warm feet immediately. The room is also cosy and warm, because there is electric underfloor heating beneath the newly tiled floor, which preheats in good time using a digital thermostat.

This is not unusual, because electric underfloor heating is often installed during renovations, because it is thinner than water-carrying systems. However, at the beginning of the construction work on the construction site in southern Hesse, it looked as though the wish for warm feet would not be able to be fulfilled. One reason for this was that cracks appeared in the screed when the old tiled floor was removed. This meant that either the screed had to be removed or a decoupling mat would have to be installed. Otherwise there would have been a risk of damage to the new tile covering after a short time. The floor also had to be sealed to prevent moisture damage. And finally, there wasn't much installation height. There was just 20 mm of room for underfloor heating, waterproofing, adhesive and covering.

Not possible with conventional systems

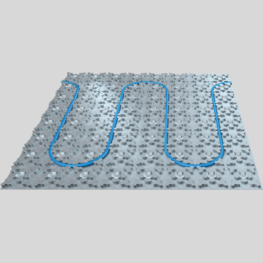

A conventional system with a fabric heating mat could not have been used in this case, since it can neither decouple nor seal against moisture. Additional waterproofing and decoupling would not have been possible due to the construction height. It is mainly due to a coincidence that the underfloor heating finally worked out: Gutjahr had just brought an underfloor heating system onto the market at the right time, and IndorTec THERM-E was the ideal solution for the construction site in southern Hesse.

3-in-1 system

Ideal for renovations: the electric underfloor heating is particularly thin – the 3-in-1 system provides waterproofing, decoupling and heating in one.

Specially for installation by tilers and floorers

The tiler was of the same opinion, and was impressed because Gutjahr developed this surface heating especially for installation by tile and floor layers. For this reason he decided to try out the system. Since he had already used other Gutjahr products and had good experiences with them, he also had no concerns. And a decoupling mat would have been important and sensible anyway to protect the new covering from damage. Because under no circumstances did the client want the old screed to be removed. With the new underfloor heating system, the processor killed two birds with one stone, combining the waterproofing and decoupling with an underfloor heating system.

Decoupling, waterproofing and heating in one system

Once all of the old tile covering and the tile adhesive had been removed, the tiler sealed the cracks in the screed with a special resin. This was followed by the installation of the underfloor heating – and therefore completely new territory. But the Gutjahr system was quick and easy to use.

- Firstly, the tiler rolled out the carrier mat onto the prepared substrate, cut it to size and then glued it all over with adhesive mortar. Thanks to having optimum flatness, this is easily possible and similar to a “classic” decoupling mat.

- He then measured the volume resistance of the heating cable, recorded it and clipped it into the "bones". Thanks to the radial cable routing, the cables are not damaged, and no heat build-up occurs. The cables always have the same cross-section regardless of their length, which means that they are clipped into place quickly and precisely, making this “electrical work” a piece of cake for the tiler.

- Then the mat joints and edge joints were sealed with sealing tapes and a liquid plastic.

- The tiler now had to check the volume resistance again. Only the main connection of the heating to the power grid was carried out by an electrician.

After laying the underfloor heating, the tiler had to carry out the "normal" tiling work. The new tiles were laid fresh-in-fresh directly onto the underfloor heating. The open structure of the mat makes it possible to fill it with tile adhesive very quickly. All in all, this saved a tremendous amount of time and energy. The new floor covering was laid within a day – together with the underfloor heating.

System with learning capability

The owners are very enthusiastic about the new underfloor heating and glad that it came onto the market at the right time. They also thought it was great that the tiler could do practically all of the work. The client also finds it very practical that the system can learn. The digital thermostat remembers when it has to heat up in order to reach the preset temperature in the morning. So that the client has comfortably warm feet just after getting up.

Products used

Similar project reports

![[TRL] Gutjahr Systemtechnik GmbH - Komplettsysteme für den Außen- und Innenbereich](/build/images/gutjahr-logo.d62773db.svg)